CAPA: Understanding Compliance, Audits, and Pharmaceutical Standards

When a drug company finds a problem—like a contaminated batch, a mislabeled bottle, or a failed stability test—they don’t just fix it and move on. They use CAPA, a formal system for Corrective and Preventive Action used in pharmaceutical manufacturing and quality control. Also known as corrective and preventive action, it’s the backbone of keeping medicines safe and meeting global standards like those from the FDA and ICH. Without CAPA, small errors can turn into recalls, lawsuits, or worse—harm to patients.

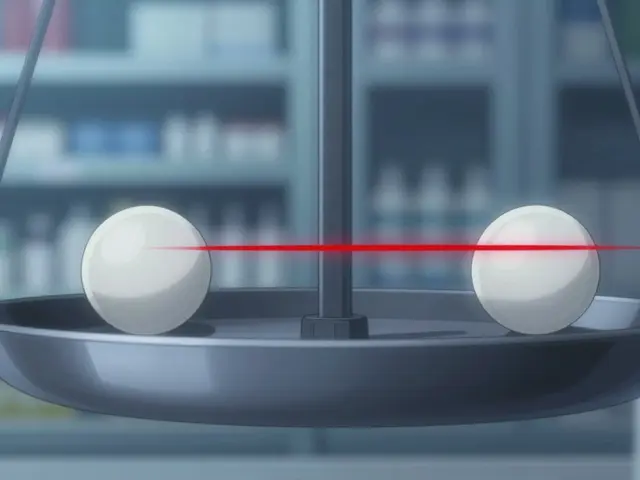

CAPA isn’t just paperwork. It’s a cycle: identify the problem, figure out why it happened, fix it, then make sure it never happens again. That’s the "corrective" and "preventive" part. You’ll see CAPA pop up in posts about ICH guidelines, drug harmonization, the global effort to align safety and quality rules across countries, and even in how companies handle medication safety, the process of ensuring drugs don’t cause harm due to errors in production or labeling. If a nurse spots a dosing error with dorzolamide-timolol, a common eye drop for glaucoma, or a pharmacist notices inconsistent labeling on generic warfarin, a blood thinner with narrow safety margins, they trigger a CAPA. It’s not about blame—it’s about learning.

Every post in this collection ties back to CAPA in some way. Whether it’s comparing Baycip (ciprofloxacin), an antibiotic with strict storage and labeling rules to alternatives, checking how budesonide, a steroid used for IBD is manufactured under tight controls, or analyzing why Indinavir, an older HIV drug got replaced by safer options, the same rules apply. Quality isn’t an accident. It’s built into every step—and CAPA is the system that catches the gaps. You’ll find real examples here: how a typo on a label led to a full process review, how a supplier’s change triggered a new validation protocol, or how a single lab error changed how an entire batch is tested. This isn’t theory. It’s what keeps your medicine working—and safe.

Corrective Actions: How Manufacturers Fix Quality Problems

Corrective actions in manufacturing go beyond fixing defects-they eliminate root causes to prevent recurrence. Learn how structured CAPA processes, backed by FDA and ISO standards, reduce defects, cut costs, and ensure compliance.

Continue Reading